CP Forged Pistons Honda B16 B16A SC7116X 81.5mm 11.1:1

| Make | Engine | Bore | Size | CH | CC | CR | Material | Process |

| Honda | B16A | 81.5mm | +0.5mm | 1.181 | 7.7 | 11.1:1 | 2618 | Forged |

CP Pistons has earned its place as one of the best Piston Manufacturers in the world by continuously keeping an extensive inventory of pistons for various applications in stock and ready to ship. Their forged 2618 series of pistons is strong enough to hold up to the beating we put on our engines without breaking our wallets.

CP Honda® pistons are available standard or oversized. CP pistons are compatible with

oversize valves and higher lift cams. Specific X designated part numbers in corporate

an X-style forging for additional strength, durability and weight reduction. Along with

full radius dome designs, high performance rings and lightweight pins, CP pistons

represent the highest quality and are engineered for maximum power. Pistons can be

ordered with skirt coating if desired. Head gaskets also available.

|

| - Standard Features | - Optional Features | |

Radiused domes are used to maximize quench while eliminating possible

hot spots that promote detonation.

|

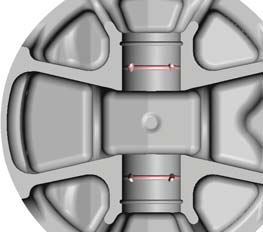

Lateral Gas Ports

Lateral Gas Ports are channels drilled at the bottom of the top ring land that assist in ring seal. These channels allow combustion gasses to enter behind the top ring and improve ring seal by forcing the ring against the cylinder wall during combustion. Skirt CoatingSkirt Coating offers additional lubricant in times of extreme heat or heavy wear situations. Coating can help by limiting the amount of friction on the skirt and providing a buffer between the piston and the cylinder. X-ForgingsX-Forgings are designed to minimize friction and reduce weight without compromising strength. With the use of bracing and ribs, the forging is configured by adjusting the weight balance between high and low stress areas. This design enables the use of a shorter pin for added strength and weight savings. | |

| - Details | ||

|

Accumulator Groove

Accumulator groove is a Vshaped groove machined in the 2nd ring land to collect excess blow-by between the top and second ring. This groove collects residual gasses during combustion and alleviates top ring flutter while increasing ring seal.

Accumulator Groove Accumulator groove is a Vshaped groove machined in the 2nd ring land to collect excess blow-by between the top and second ring. This groove collects residual gasses during combustion and alleviates top ring flutter while increasing ring seal.

|

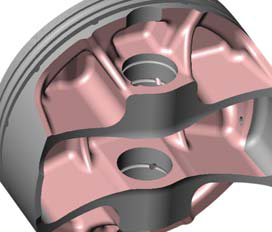

Forgings

Double pin oilers, in conjunction with our dual fed reservoir, add twice the amount of oil from the cylinder wall to the wrist pin.

CP Groove CP groove stands for Constant Pressure Groove. This groove works as a channel on the lower part of the top land that equalizes pressure to the back of the top ring groove. When used in combination with lateral gas ports, the CP groove helps keep gas ports clear of carbon build up. In addition, the CP groove prevents the top land from smudging into the top ring if the land rubs the cylinder bore. |

| - Ring End Gap Chart | |||

| Application | Top Ring | Second Ring | Oil Ring |

| Street / Hi Performance | Bore x .0045" | .004" - .008" Bigger than Top Ring | Min..015" Do not file |

| Drag Racing Road Racing | Bore x .005" | .004" - .008" Bigger than Top Ring | Min..015" Do not file |

| Nitrous / Turbo Supercharged | Bore x .0055" | .004" - .008" Bigger than Top Ring | Min..015" Do not file |

| - Ring Info | ||

|

Ring Recommendations

Failure to check ring gap can result in severe engine failure. The following end gap recommendations are general guidelines. The best ring gap for any particular engine and application varies. Increased clearance is generally needed for forced induction, nitrous, filled blocks, endurance racing and other extreme applications. The final end gap suitable for the engine is the full responsibility of the engine builder. If you have any questions, please call us for technical support. Determining Ring GapTo determine the ring end gap look for your application in the proceeding table.

|

Ring Gap Measuring Procedures

Honing Recommendations GAS NITRIDED, CPN AND CPN2 PISTON RINGS CHROME RINGS ALL RINGS |

CP Pistons is backed by some of the brightest minds in the industry. This core group allows us to explore angles not possible using conventional methods. By enlisting the latest in cutting edge software packages, CP packages together creativity, experience and proven technology to bring you the best parts for your application. Our commitment to excellence continues to advance as the industry changes. This commitment has resulted in more forgings specific to certain applications, proprietary treated wrist pins and rings manufactured only for CP. Each of these aspects has been put through stringent research and development stages to ensure that our product will exceed your standards.

3D MODELINGEach forging is designed using an advanced 3D modeling software package and is qualified through a rigorous Finite Element Analysis. 3D modeling enables CP to check thicknesses and weights before manufacturing allowing us to produce the strongest and lightest part for your application.

AT CP, ALL PISTONS ARE CREATED EQUAL!Whether you are a professional racer or a weekend warrior, CP prides itself on giving you the best part possible for your applications. All pistons at CP are put through a demanding quality control system and precise computerized machining, ensuring that your piston is the best piston available.